- Description

- Feature

- Specifications

- Certificate

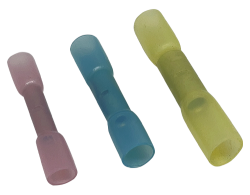

Manufacture for wiring terminals – seamless butt splice from copper tubular with tin plated. Excellent chamfered entries make wiring job be faster and easier.

The product is a form of splice that is made by joining the two ends, or butts, of two objects without any type of overlapping. There are many applications for the butt splice. Sometimes the item is used in woodworking and home renovation projects. And you can usually see it easily at the joint between wires as well. For different demands of the usage, UTA provides different types of butt splice. Each item is made under strict manufacturing procedure. No matter which type you want, just contact UTA to get the one you exactly need.

- Copper tubular brings excellent conductivity character.

A ductile metal with high thermal and electrical conductivity. UTA standard butt splices use the ETP (Electrolytic Tough Pitch) and the DHP (Phosphorus-Deoxidized, High Residual P) grade. Each terminal is tempered well for easy installation. - Seamless type butt splice

All-direction crimping. Reliable strength gets the better of seam butt splice. - Excellent chamfer treatment at both entries

Free from burrs, Quicker wire insertion faster and easier. - Quality tin plating.

Non-toxic, ductile and corrosion resistant. The excellent ductility of tin allows a tin coated base metal sheet to be formed into a variety of shapes without damage to the surface tin layer. It provides sacrificial protection for copper, nickel and other non-ferrous metals. - Military standard compliant.

- Electric current rating: AWG 22 -18: 17 A, AWG 16 -14: 30 A, AWG 12 -10: 50 A

- US military standard compliant.

- Approval: RoHS, UL (File No. E155361)

| Part. No | Wire mm2 | Wire AWG | OD mm | ID mm | L mm | PCS / Bag | Remark |

|---|---|---|---|---|---|---|---|

| B-1 | 0.5 - 1.0 | 22 - 18 | 3.3 ( 0.130) | 1.7 ( 0.067) | 15.0 (0.591) | 6,000 | UL, cUL |

| B-2 | 1.5 - 2.5 | 16 - 14 | 4.0 (0.157) | 2.4 ( 0.094) | 15.0 (0.591) | 5,000 | UL, cUL |

| B-5 | 4.0 - 6.0 | 12 - 10 | 5.5 (0.217) | 3.6 (0.142) | 15.0 (0.591) | 3,000 | UL, cUL |

| B-8 | 10 | 8 | 7.0 (0.276) | 4.5 (0.177) | 21.0 (0.827) | 500 | |

| B-14 | 14 | 6 | 9.0 (0.354) | 6.4 (0.252) | 27.5 (1.083) | 100 | |

| B-22 | 22 | 4 | 11.4 (0.449) | 8.2 (0.323) | 30.5 (1.201) | 100 | |

| B-38 | 38 | 2 | 13.3 (0.524) | 10.1 (0.398) | 33.5 (1.319) | 100 | |

| B-60 | 60 | 1/0 | 15.4 (0.606) | 12.0 (0.472) | 36.0 (1.417) | 100 | |

| B-70 | 70 | 2/0 | 17.4 (0.690) | 14.0 (0.550) | 37.8 (1.490) | 100 | |

| B-80 | 80 | 3/0 | 19.4 (0.764) | 15.4 (0.606) | 39.5 (1.555) | 100 | |

| B-100 | 100 | 4/0 | 22.0 (0.866) | 17.6 (0.693) | 39.5 (1.555) | 100 | |

| B-150 | 150 | 250–300 | 26.0 (1.024) | 20.9 (0.823) | 55.5 (2.185) | 50 | |

| B-180 | 180 | 300 - 350 | 28.6 (1.126) | 22.0 (0.866) | 58.5 (2.303) | 50 | |

| B-200 | 200 | 400 | 32.5 (1.280) | 25.7 (1.012) | 64.5 (2.539) | 50 | |

| B-325 | 325 | 500 - 600 | 37.0 (1.457) | 29.0 (1.142) | 73.5 (2.894) | 50 | |

| B -1A | 0.5 - 1.0 | 22 - 18 | 2.9 (0.114) | 1.9 (0.748) | 15.0 (0.591) | 6,000 | |

| B -2A | 1.5 - 2.5 | 16 - 14 | 3.5 (0.138) | 2.5 (0.984) | 15.0 (0.591) | 5,000 | |

| B -5A | 4.0 - 6.0 | 12 - 10 | 5.0 (0.197) | 3.6 (0.142) | 15.0 (0.591) | 3,000 | |

| B-8A | 10 | 8 | 7.0 (0.276) | 5.2 (0.205) | 21.0 (0.827) | 500 |